Our Services

Design & Engineering

Design & Engineering

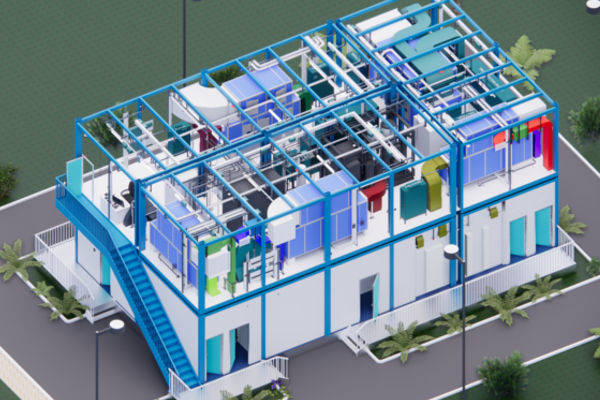

In modular construction, a significant proportion of the work in a project is conducted in a factory, the produced units are transported and then assembled onsite. As these modules can start working as soon as they are installed on the required destination, there is minimal civil work required, which saves approximately 15 – 20 % of the cost of building. As there won't be any construction required on-site, it reduces on-site labor cost by 40 – 45 %, while providing 100% quality assurance.

Instead of a typical on-site productivity level of 80 percent (due to logistics, lay down constraints, etc.), an off-site build can run at 100 to 140 percent productivity level utilizing overtime when required. As production and onsite work are conducted concurrently, the project duration is reduced significantly. Hence, the building time of the facility goes down by 30 - 35%. Modular facility will complete 30 - 50 % faster than conventional facility.

Productivity, shorter project duration, higher quality, and better occupational safety, owing to the controlled work environment of a factory. Thus, it is a more sustainable construction method.

The modules all together will have the production and technical area within them which include the following:

Modular Cleanroom System

Modular Cleanroom System

Flooring

Flooring

Utilities

Utilities

Black Utility Piping

Black Utility Piping

Process Equipment

Process Equipment

Electrical and Lighting System

Electrical and Lighting System

Environmental Monitoring System (EMS)

Environmental Monitoring System (EMS)

Building Management System (BMS)

Building Management System (BMS)

Extra Low Voltage System (ELV)

Extra Low Voltage System (ELV)

Heating Ventilation Air Conditioning (HVAC) System

Heating Ventilation Air Conditioning (HVAC) System

The modules will be designed to accommodate the loads of all the utilities and equipment installed within the modules and takes into consideration the seismic loads, wind loads, and snow loads as per design code being followed, which will play a major role depending on the destination of the facility.

The entire facility is compliant with all cGMP, WHO, USFDA and EU guidelines while being compact. The man and material movements within the facility are compliant with GMP as well. All the equipment selected for running of the facility will be compliant with all GMP requirement.

From a standardized, prefabricated cleanroom unit to a predesigned turnkey facility is not a quantum leap, but a mind-set changes to a standardized, off-the-shelf approach. Instead of spending copious amounts of hours on new designs, essentially re-inventing the wheel, these designs utilize and employ industry best practices, which results in speed and reduced costs.

Therefore, we are offering a complete modular turnkey solution with all the qualities of a pharmaceutical facility in a faster, finer, and cost-effective way.